An important shipment is stalled over a missing QA form while the shop floor produces costly scrap from an outdated engineering drawing.

This isn’t a hypothetical scenario. It's happening right now in manufacturing facilities across the country.

The American Society for Quality calls this the 'Cost of Poor Quality,' and estimates it can reach 15–20% of sales revenue.

For a $50 million manufacturer, that's up to $10 million in preventable losses annually. Every misplaced document and outdated spec sheet feeds into this number through scrap, rework, and production delays.

A DMS for manufacturing is the solution to this chaos.

Why Manufacturers Need a DMS

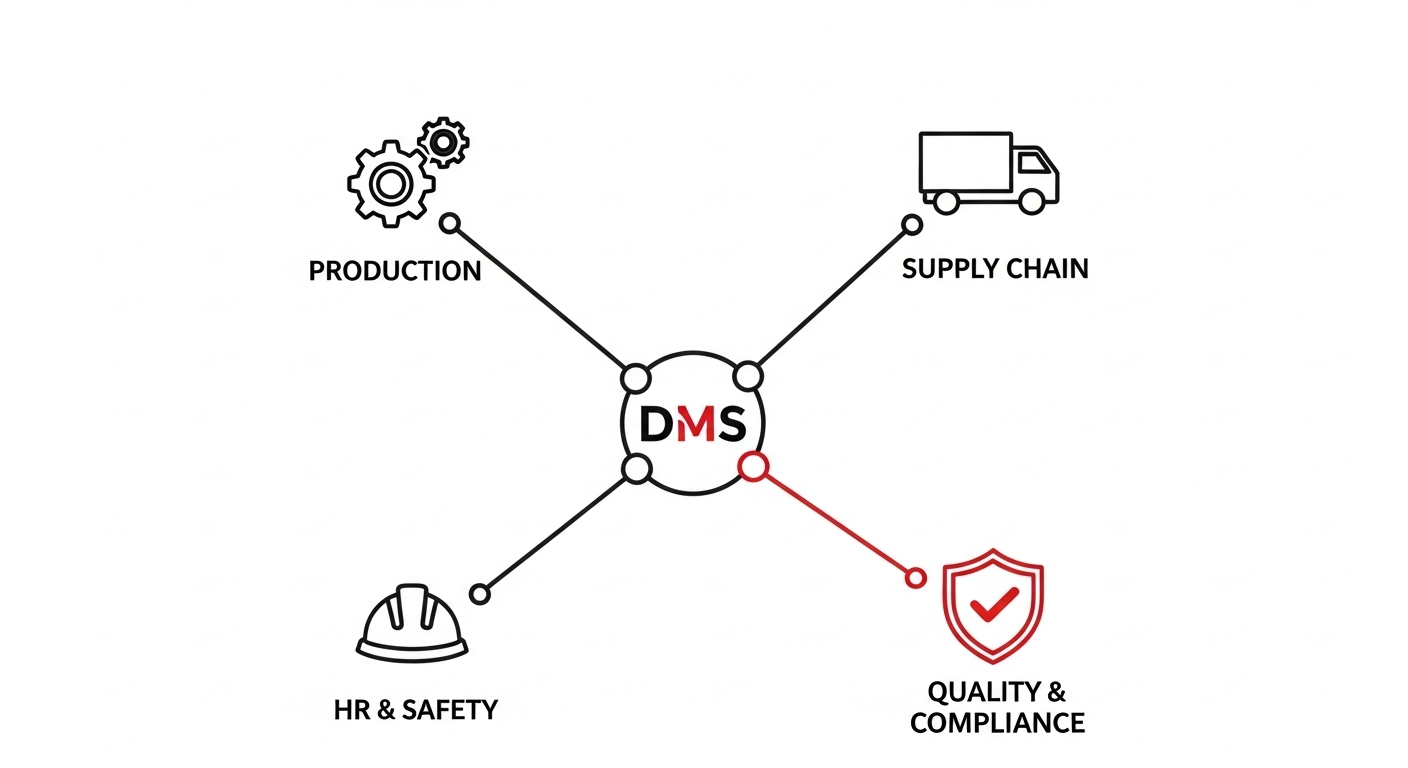

A Document Management System (DMS) is a software solution that organizes and controls your day-to-day operational documents, like work orders, invoices, and quality reports.

You might also hear the term ECM (Enterprise Content Management), which refers to a broader system that manages all of a company's information for its entire lifecycle.

Feature differences aside, for a manufacturer, the goal of both is the same: to get the right information to the right person at the right time, every time.

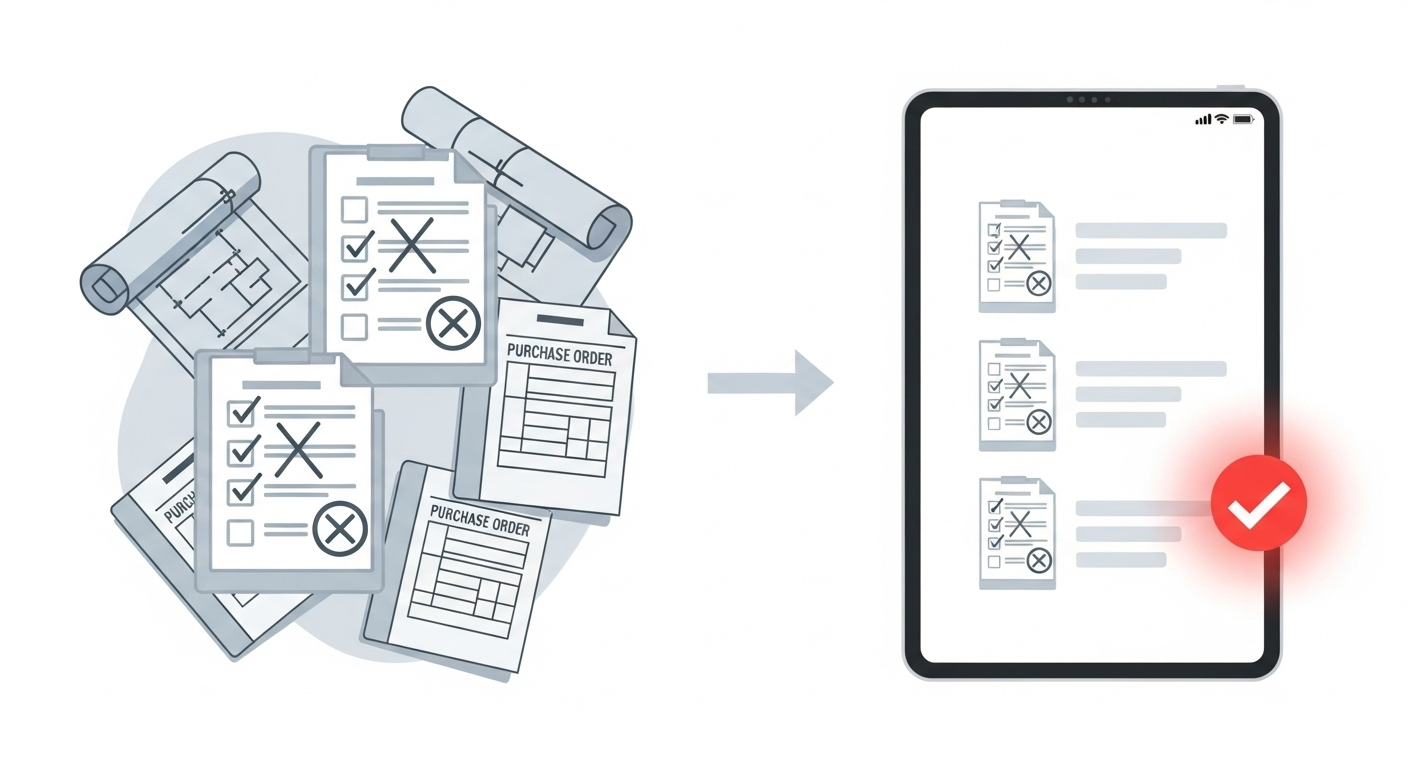

How to Use a DMS in Manufacturing

A DMS isn’t just for office files. It can also be used for the shop floor. Here’s how it solves some of manufacturing’s biggest operational challenges:

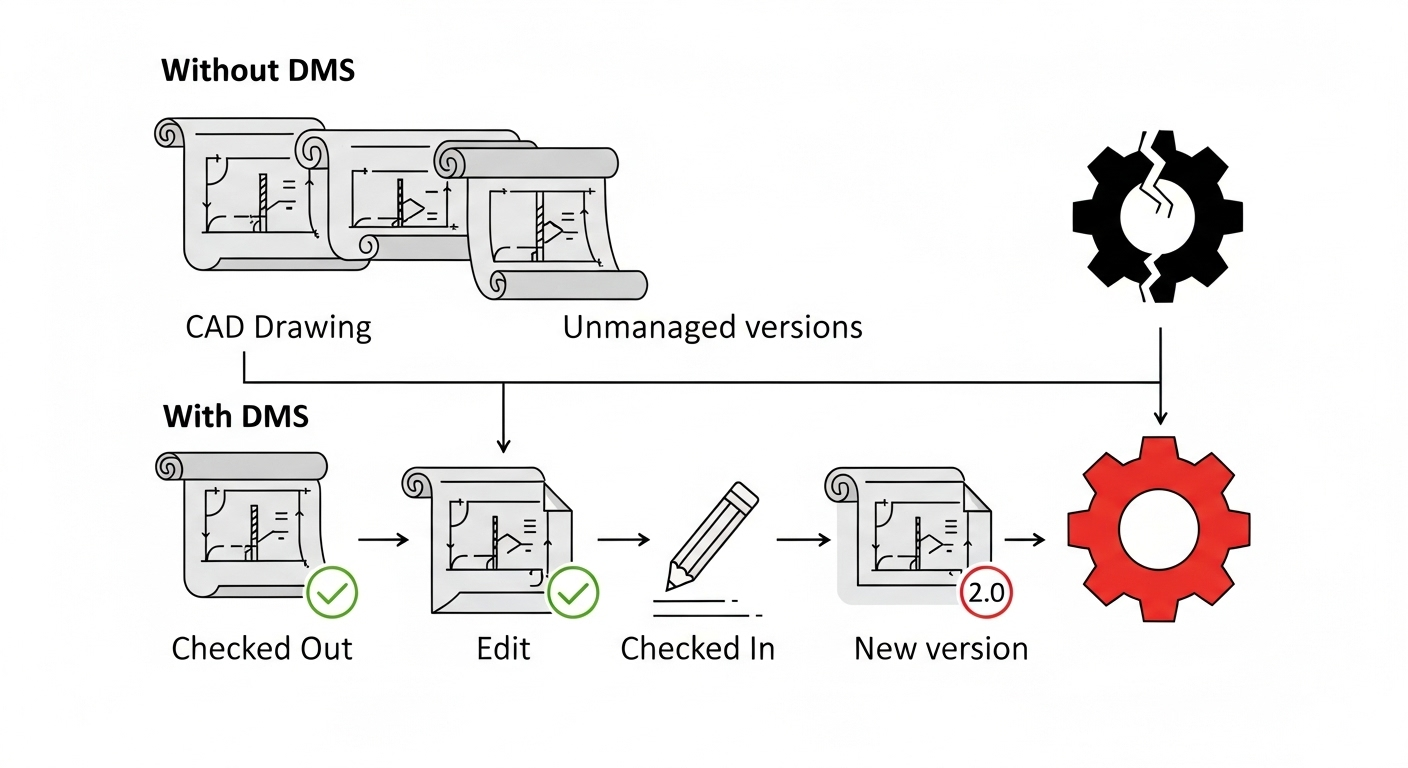

Use Case 1: Master Version Control for Engineering Documents

An engineer makes a small but critical change to a CAD file. This becomes a major risk when, according to an Autodesk study, engineers can spend up to one-third of their day on non-value-added work like searching for data.

When the team on the floor can't be certain they have the right file, they may access an old version from the shared drive.

Consequently, they might end up making an entire batch of parts based on the wrong specifications.

When a drawing is stored in a DMS, there is only one "master" file. To edit it, an engineer must "check out" the document, which locks it for everyone else.

When they save their changes and check it back in, the system automatically creates a new version and archives the old one.

This simple, controlled process makes it impossible for someone to accidentally use an outdated drawing. This directly leads to the elimination of costly rework, a dramatic reduction in material scrap, and a higher first-pass yield.

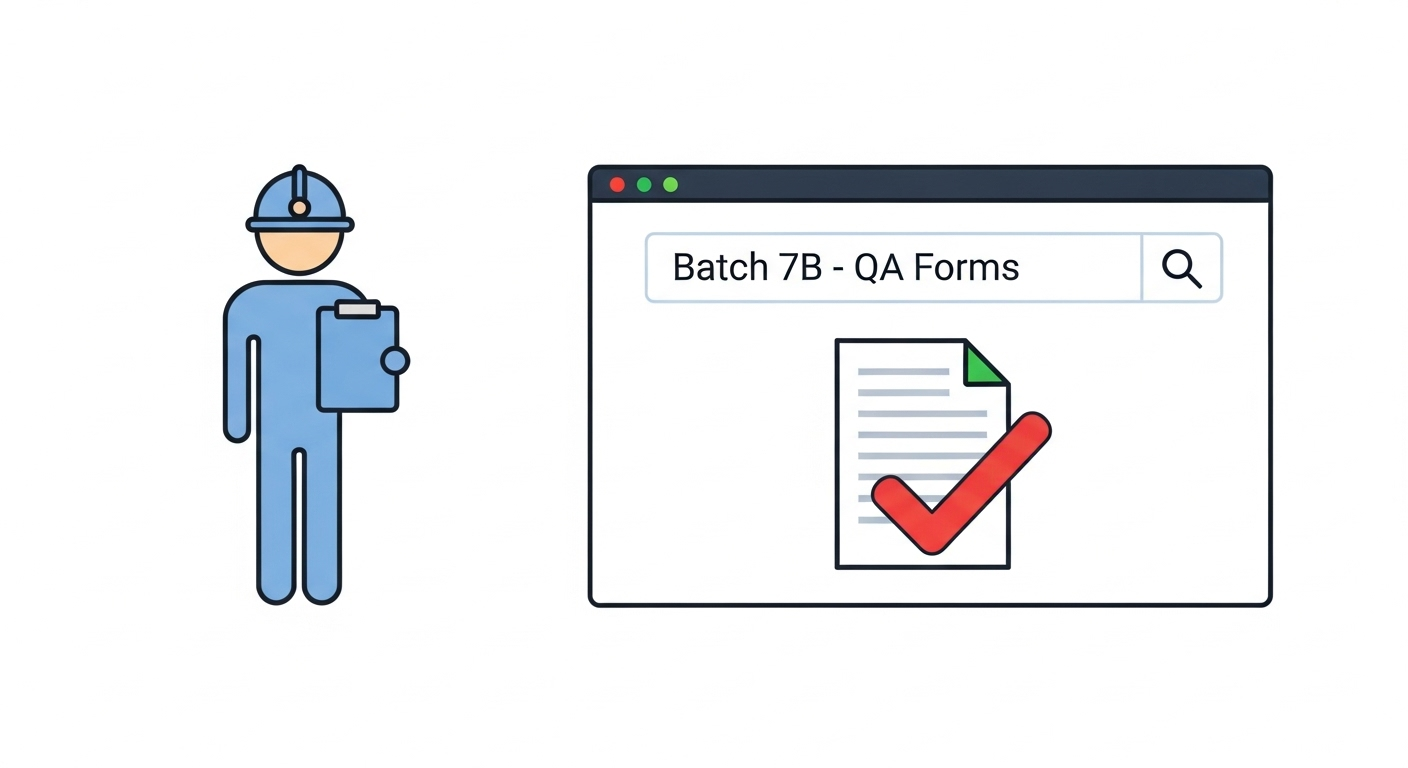

Use Case 2: Streamline Quality Control and ISO 9001 Compliance

Your quality manager has to prepare for an ISO 9001 audit. This means they have to spend days, or even weeks, searching for the right quality check forms, calibration records, and non-conformance reports just to prove you're following your processes.

Every quality document, from checklists to corrective action reports, is scanned or filed directly into the DMS and tagged with relevant information like the batch number and date.

When the auditor asks for a specific record, you can find and present it in seconds.

This turns a stressful, week-long fire drill into a simple, straightforward review.

You achieve effortless audits, maintain your critical certifications without hassle, and can prove your commitment to quality at a moment's notice.

Use Case 3: Manage Supply Chain Documentation

A shipment of raw materials you absolutely need for your manufacturing processes arrives, but the accounts payable team can't find the original purchase order to match it against the invoice and the bill of lading.

If you can’t pay, you can’t use the materials.

The result is wasted labor hours and penalties, and possibly a jeopardized vendor relationship.

The DMS links all related supply chain documents together.

The purchase order, bill of lading, and final invoice are all stored as part of the same transaction record, allowing your team to perform a "three-way match" instantly.

This makes your supply chain more resilient and profitable.

You can approve payments faster to capture early-payment discounts, resolve vendor discrepancies in minutes, and maintain a complete, auditable history for every transaction.

Use Case 4: Automate Employee Training and Safety Records

An [OSHA compliance](https://www.egnyte.com/guides/governance/osha-compliance#:~:text=work-related injuries.-,What Is OSHA Compliance%3F,the federal Department of Labor.) officer is on site and asks for the safety training records for a specific machine operator. Sifting through a filing cabinet hoping the certificate is there is a risky gamble, especially when OSHA penalties can exceed $16,000 for a single serious violation.

Each employee has a digital file in the DMS containing all their certifications and training records.

You can set automated reminders for when a certification is about to expire to create a proactive system to manage workforce compliance.

This makes your workplace dramatically less risky and your workforce safer.

In case of an incident or audit, you can immediately produce records to demonstrate that proper training was completed and protect your company from liability.

The Benefits of a DMS for Manufacturers

When you have control over your documents, you get control over your operations. The benefits are direct and impact your bottom line.

When you have strict version control on your engineering drawings, standard operating procedures (SOPs), and work instructions, you can rest assured that your shop floor is always working from the latest, approved documents.

This reduces scrap, saves materials, and prevents wasted machine time, meaning you’re putting less money on the table for errors that shouldn’t have happened in the first place.

- Pass audits with confidence

There’s no more panicked searching when an auditor asks for a specific record.

A DMS lets you pull up any quality form, training certificate, or compliance document in seconds.

It makes ISO, OSHA, and other audits a simple, stress-free process and completely transforms your document management practices.

- Strengthen your supply chain

Instant access to linked purchase orders, invoices, and bills of lading means you can approve vendor payments faster and resolve discrepancies in minutes, not days.

When your vendors are paid on time, they're more likely to stay happy and cooperative. They’re a major factor in keeping your raw materials flowing and your supply chain running without hiccups

- Build a safer, more compliant organization

A DMS helps you maintain a complete, up-to-date record of all employee training and certifications.

Ensuring your employees are well-trained and certified keeps OSHA representatives at bay, reduces your company’s liability, makes your workplace safer, and encourages your workforce to continuously improve.

Calculate Your Potential Savings

Consider this: if document-related errors are costing your operation even 5% of revenue annually, a $20 million manufacturer could save $1 million per year by implementing proper document control.

Factor in:

- Reduced rework costs: Eliminate 80% of errors from outdated drawings

- Faster audit preparation: Cut audit prep time from weeks to hours

- Improved vendor relationships: Capture 2–3% early payment discounts

- Reduced compliance risks: Avoid OSHA penalties averaging $16,000+ per serious violation

The typical DMS investment pays for itself within 6–12 months through these combined savings.

Start Managing Your Manufacturing Documents with Dokmee

The numbers don't lie: disorganized documents are costing you money every single day.

These problems compound quickly, regardless of their cause: scrap from outdated drawings, delayed shipments from missing paperwork, or failed audits from incomplete records.

Dokmee provides the centralized document control system that modern manufacturers need to compete.

Our manufacturing-focused DMS gives you instant access to the right version of every critical document, from CAD drawings and SOPs to quality records and safety certifications.

Ready to calculate your potential savings?

Our manufacturing specialists can show you exactly how much document chaos is costing your operation and demonstrate how Dokmee can eliminate these losses.

Schedule Your Free Manufacturing DMS Assessment

Frequently Asked Questions (FAQ)

What is a DMS in manufacturing?

In manufacturing, a Document Management System (DMS) is a software solution used to control all the documents that drive production.

This includes engineering drawings, Standard Operating Procedures (SOPs), quality control forms, compliance records, and supply chain documentation.

How does a DMS help with lean manufacturing?

Lean manufacturing is focused on eliminating waste.

A DMS directly supports this by eliminating the "waste" of time spent searching for documents, the "waste" of materials from rework caused by outdated drawings, and the "waste" of motion from manual, paper-based approval processes.

Can a DMS handle engineering drawings and CAD files?

Yes, absolutely.

A key feature of a DMS for manufacturing is its ability to manage complex files like CAD drawings. It provides strict version control, so engineers can check files out for edits and check them back in. This creates a new official version and prevents anyone from using an old one.

How does a DMS help with ISO 9001 certification?

ISO 9001 requires you to prove that you are following your own quality processes.

A DMS provides the core tool for this by creating a centralized, unchangeable, and easily searchable archive of all your quality records, from inspection forms to corrective action reports, making audits simple.

Can a DMS integrate with our existing ERP system?

Yes. A good DMS can integrate with your Enterprise Resource Planning (ERP) system. This allows you to link financial data with operational documents.

For example, you can connect an invoice in your ERP directly to the original purchase order and bill of lading stored in the DMS, creating a seamless, fully auditable trail.